Products

Products

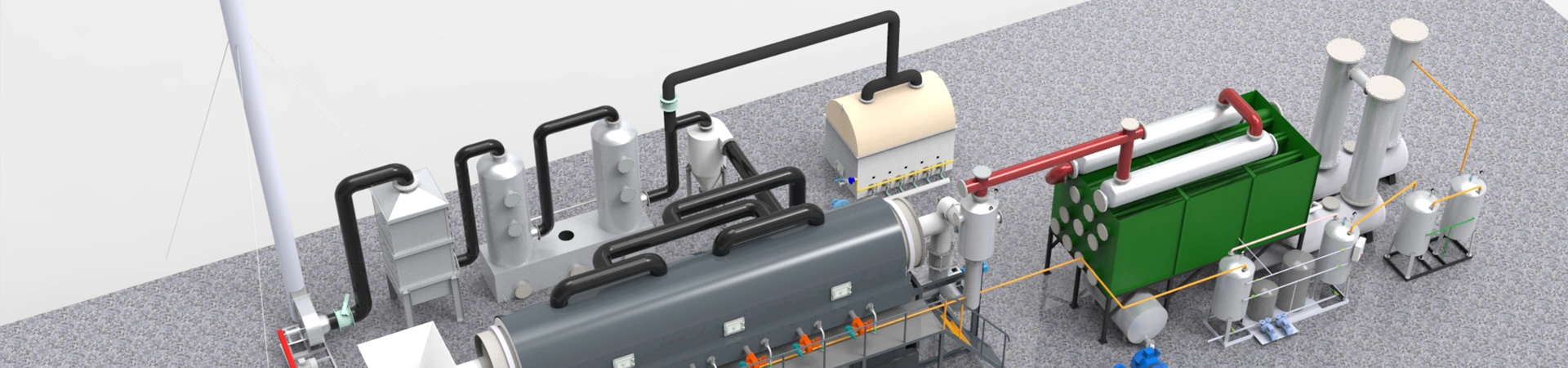

Double-layer continuous oil refining equipment

Two kinds of cooling system with the use of can really complete the heat exchange, the pyrolysis furnace within the raw material precipitation completely cooled down, to achieve the maximum collection of resolved oil, separation of non-condensable gas.

Post-slagging oil sludge refining equipment

The pyrolysis system adopts the integrated water tank cooling system, in which the horizontal cooling pipe in the water tank will be inclined at a certain angle (10-20°) so that the oil will naturally flow to the lower part.

Two sets of oil sludge refining equipment

The pyrolysis system adopts the integrated water tank cooling system, in which the horizontal cooling pipe in the water tank will be inclined at a certain angle (10-20°) so that the oil will naturally flow to the lower part.

Six sets of oil sludge refining equipment

The pyrolysis system adopts the integrated water tank cooling system, in which the horizontal cooling pipe in the water tank will be inclined at a certain angle (10-20°) so that the oil will naturally flow to the lower part.

Four sets of combined front discharge sludge refining equipment

The pyrolysis system adopts the integrated water tank cooling system, in which the horizontal cooling pipe in the water tank will be inclined at a certain angle (10-20°) so that the oil will naturally flow to the lower part.

The distillation process of used engine oil is a set of distillation kettle with preheating device, which is mainly operated at atmospheric pressure and assisted by decompression operation.