Products

Post-slagging oil sludge refining equipment

Category:

Oil sludge refining equipment

Tel:

E-mail:

Introduction

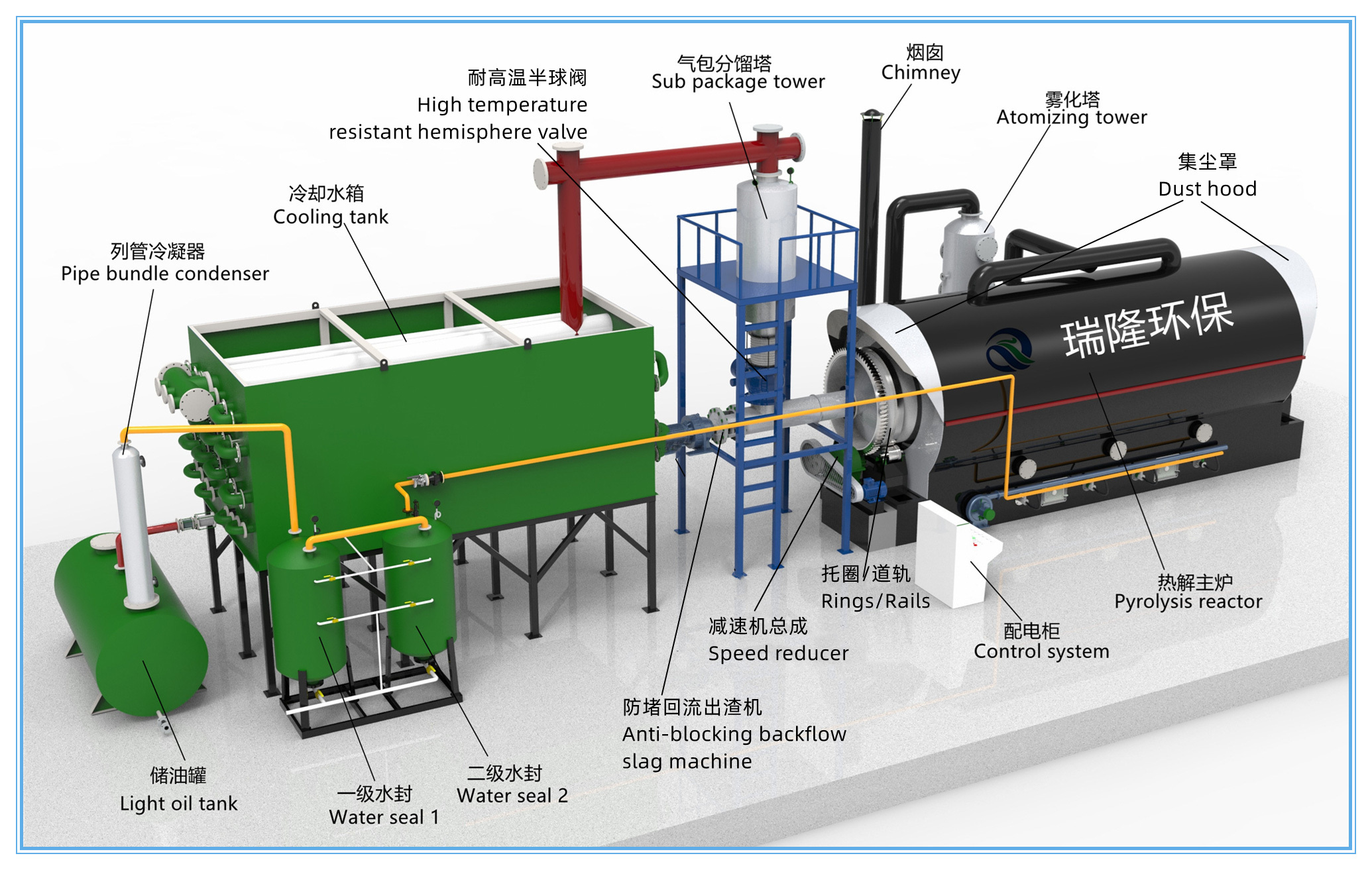

Main Furnace Description: Because the common oil sludge, oilfield waste, tar sludge (mud) in the composition is not uniform, containing part of the coke, asphaltene and a certain amount of water, so the heating and treatment process is very easy to produce coking and sticking to the wall, so this program selects the rotary furnace.The biggest feature of the rotary furnace pyrolysis equipment is that it has a good mixing effect on the material, which can get a more uniform pyrolysis product. Adopting inter-wall heating method, the material does not directly contact with oxygen and oxidization reaction does not occur, so it will not produce dioxin. There are various choices of heating fuels for this system, such as coal, oil, natural gas, fly ash, biomass, lava rock, hot air, etc.

Description of slag discharging system: The content of solidified materials in hazardous wastes such as oily sludge, oilfield waste, tar slag (mud) is high, and the residue after pyrolysis carbonization is completed requires a long time to cool down, which will affect the production efficiency. The pyrolysis treatment equipment designed by Ruilong Company adopts closed high-temperature slag discharge device, which can transport the residue out of the furnace at a high temperature of about 180℃, and transfer it to the outside of the furnace to cool down through the multi-stage water-cooled spiral slag discharge machine.

Anti-coking wall clearing device: Oil-containing sludge, oilfield waste, tar slag (mud) and other hazardous wastes, containing asphalt, paraffin and gum, etc., in the heating process, it is easy to form a coking layer in the inner wall of the furnace, which affects the heating speed of the material, the reaction, the service life of the equipment and the productivity, and in serious cases, it will also make the outlet of the furnace chamber blocked and forced to stop the furnace; and the material is easy to clumping clumps, which affects the slagging and the production efficiency. Ruilong company exclusive R & D and design of anti-coking wall clearing device, fixed in the pyrolysis furnace, can realize real-time wall clearing, do not give the material coking enough time to stay.

Pyrolysis furnace inner wall clearing effect show (raw material for Shaanxi Shenmu's coal tar slag)

HW11 coal tar slag raw material photos

Condition of the furnace wall at the end of production

The residue is in the form of powdered crumbs

Description of integrated water tank cooling system: The pyrolysis system adopts the integrated water tank cooling system, in which the horizontal cooling pipe in the water tank will be inclined at a certain angle (10-20°) so that the oil will naturally flow to the lower part. The inlet pipe is φ325, with an inclination angle of ~20°; the middle pipe is φ219, with an inclination angle of ~15°; the outlet pipe is φ108, with an inclination angle of ~10°, and the oil will converge at the blind plate protruding from the two ends, and then flow into different pipes. When the oil is just precipitated, the flow is larger and there are more impurities, the thicker cooling pipe can make the impurities precipitate at the bottom of the pipe, which has less influence on the oil and is not easy to be clogged; the design of one-piece water tank is convenient for transportation and installation. The two ends of the cooling water tank are sealed by blind plates and connected by screws, when cleaning and maintenance, only need to open the blind plates at both ends, and use the pipe slightly longer than the cooling pipe with the stopper smaller than the inner diameter of the pipe to dredge and clean up, easy and convenient to operate.

Tank Cooling System

Raw material reference photos

Pyrolysis equipment effect reference diagram

| Pyrolysis equipment related technical parameters | ||

| Reference number | Sports event | Element |

| 1 | Applicable materials | Tar sludge, oily sludge and other organic wastes |

| 2 | Material pre-processing | Simple dehydration, decontamination, etc. (not mandatory) |

| 3 | Material oil yield | Depending on the oil content of the material itself, the extraction rate is 98%. |

| 4 | Main Furnace Door Type | Optional: Center round door, oval door, square door, full door, shaped door (Door size: φ1.5m, φ1.8m, etc.) The rate is 98%. |

| 5 | Main Furnace Size | Optional customizable: φ2600mm*6600mm; φ2600mm*8000mm; φ2800mm*6600mm; φ2800mm*7700mm; φ2800mm*8000mm; φ2800mm*8800mm |

| 6 | Daily Capacity | 8 tons, 10 tons, 12 tons, 15 tons, etc. |

| 7 | Transmission mode | Two-point support, external gear ring rotation |

| 8 | Control system | Optional: semi-automatic, automatic, intelligent PLC |

| 9 | Forms of construction | Horizontal, Rotary |

| 10 | Working Pressure | Atmospheric pressure, micro-negative pressure |

| 11 | Rotation speed of main engine | 0.4r/m |

| 12 | Heating Fuel | Natural gas, fuel oil, etc. |

| 13 | Heating method | Direct heating in the combustion chamber at the bottom of the main furnace or indirect heating in the hot air furnace |

| 14 | Installed power | 27-35KW/h |

| 15 | Static (in a signal) | <85dB |

| 16 | Cooling medium | Water cooling, recycling |

| 17 | Slagging method | Optional: low-temperature slagging, high-temperature slagging; front slagging, back slagging |

| 18 | Discharge treatment | Optional: desulfurization, dust removal, deodorization, denitrification, denitrogen oxides, etc. |

| 19 | Installation | On-site guided installation, optional unitized assembly, skid-mounted design |

| 20 | Foundations (of a building) | 15cm concrete floor installation or make a sunken foundation |

| 21 | Forms of work | Options: intermittent, semi-continuous, continuous |

| 22 | Weight per set | 20-50Ton, conventional equipment around 35T |

| 23 | Footprint (of a building, piece of equipment etc) | Conventional equipment: a single set covers an area of about 200 square meters, multiple sets of joint groups save more space |

| 24 | Staffing | Conventional equipment: 3-4 people to operate, multiple sets of joint group more labor-saving |

| 25 | Production Cycle | Conventional equipment: about 20 days |

| 26 | Haulage | Conventional equipment: single set of 1~2 17.5m flatbed trucks, more sets are more economical |

| 27 | Installation period | Conventional equipment: about 20 days for a single set, 30 days for two sets. Multi-set group saves more time |

Key words:

Post-slagging oil sludge refining equipment

Previous:

Message

Related Products