Products

Skid-mounted container refinery equipment

Category:

Waste tire oil refining equipment

Tel:

E-mail:

Introduction

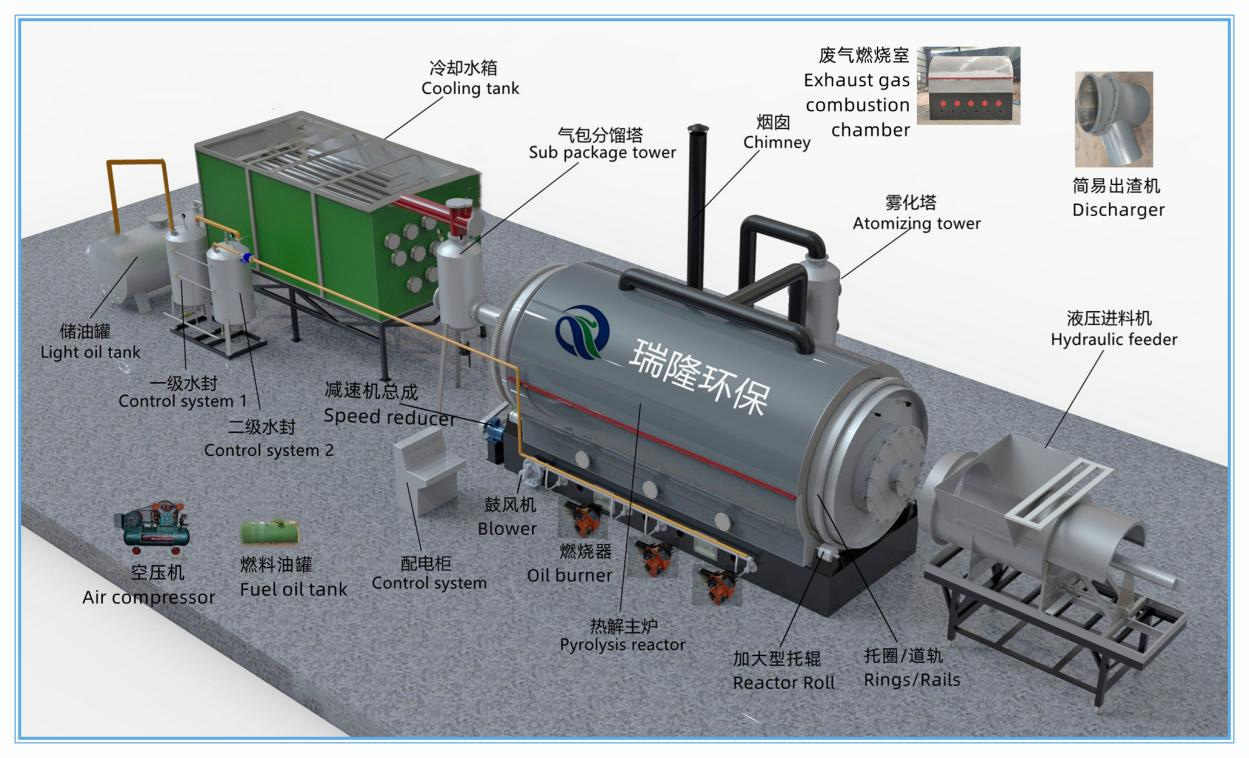

Equipment: one of the most advanced equipment in pyrolysis industry with high degree of automation, high product generation rate and quality, fast production speed, strong safety and easy operation.

One-piece main furnace casing: adopts one-piece design, good heat preservation effect, and easy to transport and install.

The two ends of the main pyrolysis furnace are increased with one-piece lathe-machined pallets, which makes the equipment run more smoothly, minimises the vibration effect at the air outlet, effectively reduces the oil and gas leakage problem, and reduces the failure rate of the sealing part.

Enlarged support wheels: This set of equipment adopts the latest self-adjusting drag wheels, which can effectively decompose the stress point of supporting the furnace body and make the pyrolysis equipment run more smoothly, safely and reliably.

Exclusive R&D and design of main furnace anti-sticking wall device, which can effectively reduce the problem of material sticking to the wall in the production process. The device can reduce the cleaning frequency, shorten the maintenance time and maintenance cost of the equipment, increase the production time and prolong the service life of the main furnace.

Enhanced sealing design, effectively improve the safety of the equipment and environmental protection.

Tank-type cooling system: One-piece tank design, easy to transport and install. The cooling pipe is placed in the water and the cooling tower works together to circulate the cooling of condensable oil and gas, with good cooling effect, high oil yield, good oil quality and long service life. The elbows at both ends are easy to dismantle and easy to clean and maintain.

Gas recovery system: non-condensable gas is returned to the furnace chamber for full combustion through two-stage safety water seal, which not only saves combustion, but also avoids causing secondary pollution.

Tyre pyrolysis equipment reference diagram

| Technical Parameters of Pyrolysis Carbonisation Equipment | ||

| Serial number | Sports event | Element |

| 1 | Applicable materials | Tyres, rubber, plastic products, oily sludge and other organic solid waste |

| 2 | Material pre-processing | Cutting and crushing, compressing and bundling, drying, hot melting, emulsifying, etc. |

| 3 | Material oil yield | Depending on the oil content of the material itself, the extraction rate is 98%. |

| 4 | Main Furnace Door Type | Optional: centre round door, oval door, square door, full door, shaped door (Door size: φ1.5m, φ1.8m, etc.) |

| 5 | Main Furnace Size | Optional customisable: φ2600mm*6600mm; φ2600mm*8000mm; φ2800mm*6600mm; φ2800mm*7700mm; φ2800mm*8000mm; φ2800mm*8800mm |

| 6 | Daily Capacity | 8 tonnes, 10 tonnes, 12 tonnes, 15 tonnes, etc. |

| 7 | Transmission method | Two-point support, external gear ring rotation |

| 8 | Control | Optional: semi-automatic, automatic, intelligent PLC |

| 9 | Forms of construction | Horizontal, rotary |

| 10 | Working Pressure | Atmospheric pressure, micro-negative pressure |

| 11 | Rotation speed of main engine | 0.4r/m |

| 12 | Heating Fuel | Natural gas, fuel oil, self-produced waste gas/oil. Coal, wood, biomass fuels, etc. |

| 13 | Heating method | Direct heating in the combustion chamber at the bottom of the main furnace or indirect heating in the hot air furnace |

| 15 | Installed power | 17-27KW/h |

| 16 | Static (in a signal) | <85dB |

| 19 | Cooling medium | Water cooling, recycling |

| 21 | Slagging method | Optional: low-temperature slagging, high-temperature slagging; front slagging, back slagging |

| 22 | Discharge treatment | Optional: desulphurisation, dust removal, deodourisation, denitrification, denitrogen oxides, etc. |

| 23 | Installation | On-site guided installation, optional unitised assembly, skid-mounted design |

| 24 | Foundations (of a building) | 15cm concrete floor installation or make a sunken foundation |

| 25 | Forms of work | Options: intermittent, semi-continuous, continuous |

| 26 | Weight per set | 20-50Ton, conventional equipment about 35T |

| 27 | Footprint (of a building, piece of equipment etc) | Conventional equipment: a single set of about 200 square metres of land, multiple sets of joint group more space-saving |

| 28 | Staffing | Conventional equipment: 3-4 people to operate, multiple sets of group more labour-saving |

| 29 | Oil handling | Filtration, blending, stirring, purification distillation, etc. |

| 30 | Production Cycle | Conventional equipment: about 20 days |

| 31 | Haulage | Conventional equipment: single set of 1~2 17.5m flatbed trucks, more sets of more savings |

| 32 | Installation period | Conventional equipment: about 20 days for a single set, 30 days for two sets, and more time for multiple sets. |

Key words:

Skid-mounted container refinery equipment

Message

Related Products