Products

Double-layer continuous oil refining equipment

Category:

Continuous oil refining equipment

Tel:

E-mail:

Introduction

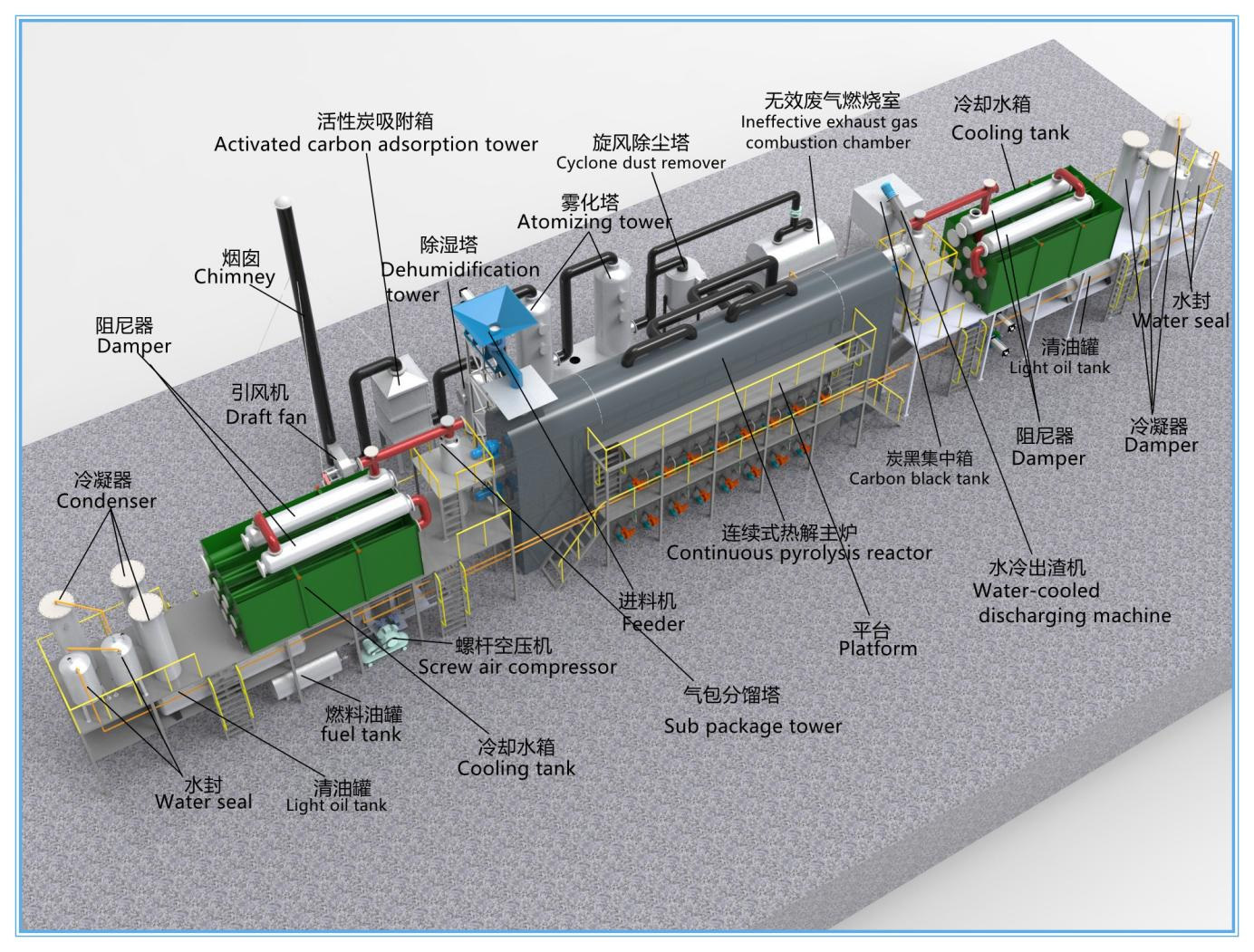

The main furnace of the continuous pyrolysis equipment is a combination of two furnaces, both of which are independent units of rotary pyrolysis furnace, and after the combination, they are connected by a spiral to achieve continuous production. The two furnaces are connected with each other, both of them are at atmospheric pressure without oxygen, but due to the different distances from the combustion chamber, the temperatures inside the furnaces are different in order to realise their respective treatment effects. The length of the single furnace is 10m, and the total travelling distance of the materials in the furnace after combination reaches 20+m, which ensures enough residence and reaction time, and can really extract the oil cleanly, and reduce the oil content of the carbon black to the minimum; the processing capacity of the whole set of device is about 1.2-1.5t/h, and the daily processing is about 30t (according to the density and composition of the materials have certain differences).

The two furnaces are stacked on top of the heating combustion chamber to maximise the use of heat energy; the non-condensable gas precipitated from the raw material is filtered by two-stage water seals and sent back to the combustion chamber to heat the main furnace, which realises energy saving and emission reduction.

Continuous pyrolysis equipment is a high-temperature operating environment, and the material is flammable, so it is very critical to complete the oxygen barrier treatment while continuously feeding the material. The feeding method of this project applies to the closed hydraulic feeding machine with nitrogen replacement system. Materials are fed into the hopper of the feeder by bucket trucks, grabbers and other auxiliary tools, pushed into the replacement bin by hydraulic presses, and then transported into the main furnace after replacing the oxygen with nitrogen. The feeding system is more applicable, for solid, semi-solid, fluid materials can be universal. And the raw materials only need to remove or crush the larger solid impurities, without three-phase separation or fine screening and other finishing pre-treatment.

Adopting closed high-temperature slagging device, the residue can be transported out of the furnace at a high temperature of about 180~380℃, and transferred to the outside of the furnace for cooling down through multi-stage water-cooled spiral slagging machine.

Because of the high temperature and pressure environment inside the furnace, there is no oxygen entering the slagging system. Moreover, the carbon black conveying process is also a cooling process. The temperature of the slag is about 60-80℃ when it reaches the slag outlet and enters the slag concentration box.

The continuous equipment is equipped with two sets of cooling systems: First, water tank type cooling system. The oil just precipitated when the flow is larger, and more impurities, thicker cooling pipe can make the impurities precipitate at the bottom of the pipe, less impact on the oil and not easy to clog; tank cooling pipe on both sides of the blind, cleaning and maintenance only need to open the long pipeline for dredging and cleaning; one-piece water tank design, easy to transport and installation. Second, tube/tube cooler. Tube condenser has a better cooling effect, in fact, the better quality of oil, steam, etc.; covers an area of small and beautiful.

Two kinds of cooling system with the use of can really complete the heat exchange, the pyrolysis furnace within the raw material precipitation completely cooled down, to achieve the maximum collection of resolved oil, separation of non-condensable gas.

Tyre pyrolysis equipment reference diagram

| Technical Parameters of Pyrolysis Carbonisation Equipment | ||

| Serial number | Sports event | Element |

| 1 | Applicable materials | Tyres, rubber |

| 2 | Material pre-processing | Cutting and crushing, compressing and bundling, drying, hot melting, emulsifying, etc. |

| 3 | Material oil yield | Depending on the oil content of the material itself, the extraction rate is 98%. |

| 4 | Main Furnace Door Type | Optional: centre round door, oval door, square door, full door, shaped door (Door size: φ1.5m, φ1.8m, etc.) |

| 5 | Main Furnace Size | Optional customisable: φ1500mm*12000mm*2; |

| 6 | Daily Capacity | 30 tonnes |

| 7 | Transmission method | Two-point support, external gear ring rotation |

| 8 | Control system | Optional: semi-automatic, automatic, intelligent PLC |

| 9 | Structural forms | Horizontal, rotary |

| 10 | Working Pressure | Atmospheric pressure, micro-negative pressure |

| 11 | Rotation speed of main engine | 0.4r/m |

| 12 | Heating Fuel | Natural gas, fuel oil, self-produced waste gas/oil. Coal, wood, biomass fuels, etc. |

| 13 | Heating method | Direct heating in the combustion chamber at the bottom of the main furnace or indirect heating in the hot air furnace |

| 15 | Installed power | 17-27KW/h |

| 16 | Static (in a signal) | <85dB |

| 19 | Cooling medium | Water cooling, recycling |

| 21 | Slagging method | Optional: low-temperature slagging, high-temperature slagging; front slagging, back slagging |

| 22 | Emission treatment | Optional: desulfurization, dust removal, deodorization, denitrification, denitrogen oxides, etc. |

| 23 | Installation | On-site guided installation, optional unitized assembly, skid-mounted design |

| 24 | Foundations (of a building) | 15cm concrete floor installation or make a sunken foundation |

| 25 | Forms of work | Continuous |

| 26 | Weight per set | 20-50Ton, conventional equipment around 35T |

| 27 | Footprint (of a building, piece of equipment etc) | Conventional equipment: a single set occupies about 400 square meters |

| 28 | Staffing | Conventional equipment: 3-4 people to operate, multiple sets of joint group more labor-saving |

| 29 | Oil treatment | Filtration, blending, stirring, purification distillation, etc. |

| 30 | Production Cycle | Conventional equipment: about 35 days |

| 31 | Haulage | Conventional equipment: single set of 3~4 17.5m flatbed trucks, multiple sets are more economical |

| 32 | Installation period | Conventional equipment: a single set of about 20 days, two sets of about 30 days, more sets of joint group more time-saving |

Key words:

Double-layer continuous oil refining equipment

Previous:

Next :

Message

Related Products