Products

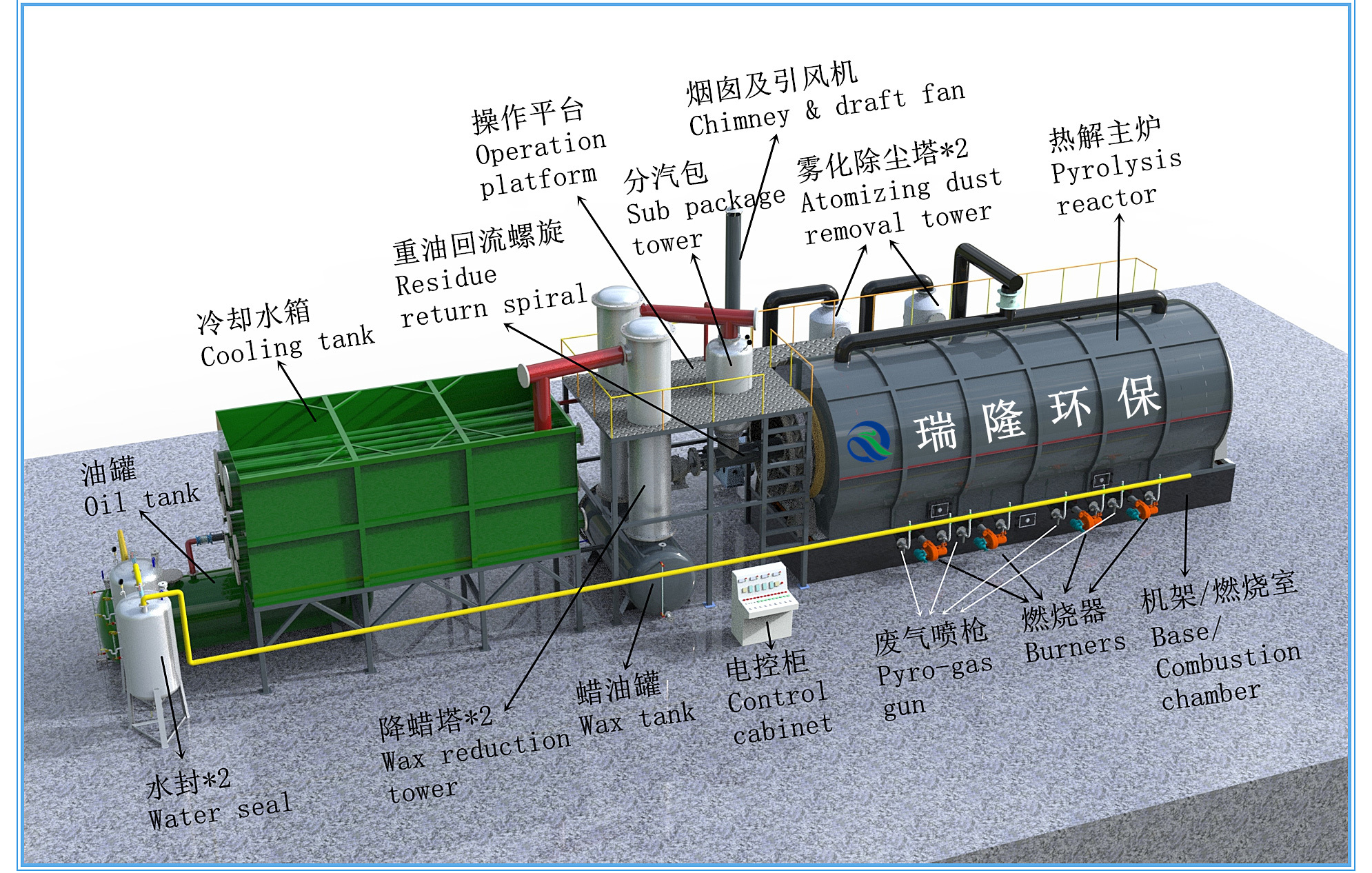

Multi-sets of waste plastics oil refining equipment

Category:

Waste plastic oil refining equipment

Tel:

E-mail:

Introduction

Main Furnace Design and Furnace Guiding Device

The system adopts horizontal rotary structure, with the following significant features:

a, according to different material properties (moisture, density, size, etc.) to change the rotary parameters, so that the material in the host can form a stable and uniform heat, quality and heat exchange more fully;

b. Strong overload resistance of the host;

c. The host realises ‘zero horizontal thrust’, which greatly reduces the wear and tear of the blocking wheel, and the cylinder runs smoothly and reliably;

d, the host adopts ‘centring type pallet device’, so that the pallet and the gear ring is always linear contact, thus greatly reducing the wear and power loss;

e. The slag end is designed with slag coping board;

The main furnace is equipped with a spiral belt-shaped guide plate, which can control the direction of the material during production and promote the movement of carbon black to the slagging end in the slagging process, so as to realise efficient slagging.

Anti-coking wall clearing device

This device is developed by Ruilong company after many years of technical research and development, and has good effect on the rotating main furnace to prevent sticking wall and coking in the process of pyrolysis of waste plastics and industrial solid wastes.

Waste plastics, industrial solid waste in the pyrolysis process, the material in the main furnace wall and the root of the spiral belt is easy to produce sticky wall phenomenon, if there is no external impact, the main furnace produced by the sticky wall is not easy to fall off, not only affect the material heating speed, reaction, equipment life and production efficiency, in serious cases, will also make the furnace chamber outlet blockage and forced to stop the furnace; and the material is easy to clumping and clumping, affecting the slagging and production efficiency.

Ruilong company exclusive R & D and design of an anti-coking wall clearing device, in the spiral belt hanging chain, and each chain hanging small forged steel ball, chain and ball with the rotation of the main furnace to form a dynamic, within the furnace wall and the rotating belt to produce impact and collision, so that the main furnace wall can not produce lumps and sticky wall, thus avoiding the occurrence of a large area of coking.

5.5. Wax reduction and dust reduction system

Petrochemical products such as waste plastics, waste aluminium plastics and industrial solid waste contain paraffin. Paraffin wax will be vaporised with the oil component in the heating link and turn into gas into the oil pipeline and cooling pipeline at the back. Wax has a low freezing point and will solidify and clump when the temperature drops. If it is blocked in the pipeline, it will cause the equipment to be pressurised and cause safety hazards.

The waste aluminium-plastic pyrolysis equipment designed by Ruilong company is equipped with a wax reduction system, which is installed after the steam ladle and before the cooling system, so that the paraffin wax can be collected in advance before it solidifies and clogs the cooling pipes. It effectively improves safety and reduces the cleaning and maintenance frequency of the cooling system.

5.6. Tank-type heat exchanger (cooling system)

The pyrolysis process is mainly divided into two major parts: heating and cooling. The material in the furnace absorbs heat and then goes from melting to vapourisation, and then becomes liquid fuel oil after cooling down and condensing by the cooling system. The pyrolysis equipment is equipped with water tank type cooling system, the advantages are as follows: the flow rate is larger when the oil is just precipitated, and there are more impurities, the thicker cooling pipeline can make the impurities settle at the bottom of the pipeline, which has less influence on the oil and is not easy to be clogged; both sides of the cooling pipe of the water tank are blind, so that when cleaning and maintenance, the blind can be opened and cleaned up; the design of one-piece water tank is easy for transport and installation. Low failure rate, simple operation and good cooling effect. It is able to cool down the oil and gas completely, realising the maximum collection of resolved oil and separation of non-condensable gas.

Tank Cooling System Cutaway view of cooling system

Equipment effect reference diagram

| Technical Parameters of Pyrolysis Carbonisation Equipment | ||

| Serial number | Sports event | Element |

| 1 | Applicable materials | Tyres, rubber, plastic products, oily sludge and other organic solid waste |

| 2 | Material pre-processing | Cutting and crushing, compressing and bundling, drying, hot melting, emulsifying, etc. |

| 3 | Material oil yield | Depending on the oil content of the material itself, the extraction rate is 98%. |

| 4 | Main Furnace Door Type | Optional: centre round door, oval door, square door, full door, shaped door (Door size: φ1.5m, φ1.8m, etc.) |

| 5 | Main Furnace Size | Optional customisable: φ2600mm*6600mm; φ2600mm*8000mm; φ2800mm*6600mm; φ2800mm*7700mm; φ2800mm*8000mm; φ2800mm*8800mm |

| 6 | Daily Capacity | 8 tonnes, 10 tonnes, 12 tonnes, 15 tonnes, etc. |

| 7 | Transmission method | Two-point support, external gear ring rotation |

| 8 | Control | Optional: semi-automatic, automatic, intelligent PLC |

| 9 | Forms of construction | Horizontal, rotary |

| 10 | Working Pressure | Atmospheric pressure, micro-negative pressure |

| 11 | Rotation speed of main engine | 0.4r/m |

| 12 | Heating Fuel | Natural gas, fuel oil, self-produced waste gas/oil. Coal, wood, biomass fuels, etc. |

| 13 | Heating method | Direct heating in the combustion chamber at the bottom of the main furnace or indirect heating in the hot air furnace |

| 15 | Installed power | 17-27KW/h |

| 16 | Static (in a signal) | <85dB |

| 19 | Cooling medium | Water cooling, recycling |

| 21 | Slagging method | Optional: low-temperature slagging, high-temperature slagging; front slagging, back slagging |

| 22 | Discharge treatment | Optional: desulphurisation, dust removal, deodourisation, denitrification, denitrogen oxides, etc. |

| 23 | Installation | On-site guided installation, optional unitised assembly, skid-mounted design |

| 24 | Foundations (of a building) | 15cm concrete floor installation or make a sunken foundation |

| 25 | Forms of work | Options: intermittent, semi-continuous, continuous |

| 26 | Weight per set | 20-50Ton, conventional equipment about 35T |

| 27 | Footprint (of a building, piece of equipment etc) | Conventional equipment: a single set of about 200 square metres of land, multiple sets of joint group more space-saving |

| 28 | Staffing | Conventional equipment: 3-4 people to operate, multiple sets of group more labour-saving |

| 29 | Oil handling | Filtration, blending, stirring, purification distillation, etc. |

| 30 | Production Cycle | Conventional equipment: about 20 days |

| 31 | Haulage | Conventional equipment: single set of 1~2 17.5m flatbed trucks, more sets of more savings |

| 32 | Installation period | Conventional equipment: about 20 days for a single set, 30 days for two sets, and more time for multiple sets. |

Key words:

Multi-sets of waste plastics oil refining equipment

Previous:

Next :

Message

Related Products