Products

Distillate

Category:

Distillate

Tel:

E-mail:

Introduction

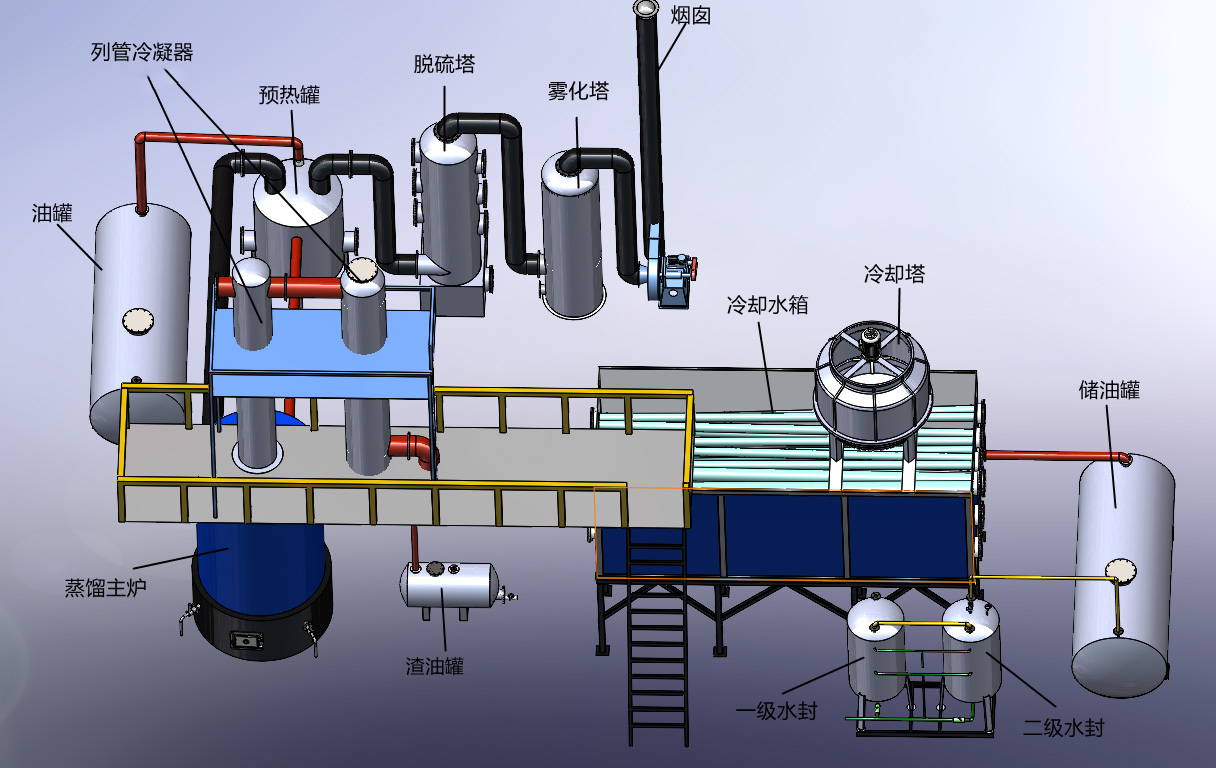

The distillation process of used engine oil is a set of distillation kettle with preheating device, which is mainly operated at atmospheric pressure and assisted by decompression operation; the distillation kettle is divided into packing tower, column cooling, negative pressure station and sand filtering device, oil conditioning device and soot treatment and other parts.

Preheating device can make full use of the residual heat generated in the distillation kettle heating to waste engine oil preheating treatment, preheating treatment can not only save fuel to improve the utilization rate of the calorific value, but also the waste engine oil may contain water evaporation, to avoid damage to the molecular sieve in the stuffing tower.

According to the quality of the oil, the process is also designed with an oil filtration sand device and a tube filter, which can intercept the suspended impurities in the oil underneath.

The process is also designed with a carbonizable and anti-coking device and automated residue discharge, which greatly reduces labor and equipment life.

Finally, the process is also designed with a mixing and blending tank, which can add adjusting agent according to the quality of the oil, and finally get the ideal oil.

Process Flow Diagram

| Pyrolysis carbonization equipment related technical parameters | ||

| Serial number | Sports event | Element |

| 1 | Applicable materials | Waste engine oil, crude oil |

| 2 | Material pre-processing | Raw material preheating |

| 3 | Material oil yield | Depending on the oil content of the material itself, the extraction rate is 98%. |

| 4 | Main Furnace Door Type | Optional: center round door, oval door, square door, full door, shaped door (Door size: φ1.5m, φ1.8m, etc.) |

| 5 | Main Furnace Size | Optional customization: φ2600mm*6600mm; φ1800mm*4000mm |

| 6 | Daily Capacity | 8 tons, 10 tons, 12 tons, 15 tons, etc. |

| 7 | Drive Type | Two-point support, external gear ring rotation |

| 8 | Control system | Optional: semi-automatic, automatic, intelligent PLC |

| 9 | Forms of construction | Horizontal, Rotary |

| 10 | Working Pressure | Atmospheric pressure, micro-negative pressure |

| 11 | Rotation speed of main engine | 0.4r/m |

| 12 | Heating Fuel | Natural gas, fuel oil, self-produced waste gas/oil. Coal, wood, biomass fuels, etc. |

| 13 | Heating method | Direct heating in the combustion chamber at the bottom of the main furnace or indirect heating in the hot air furnace |

| 15 | Installed power | 17-27KW/h |

| 16 | Static (in a signal) | <85dB |

| 19 | Cooling medium | Water cooling, recycling |

| 22 | Discharge treatment | Optional: desulfurization, dust removal, deodorization, denitrification, denitrogen oxides, etc. |

| 23 | Installation | On-site guided installation, optional unitized assembly, skid-mounted design |

| 24 | Foundations (of a building) | 15cm concrete floor installation or make a sunken foundation |

| 26 | Weight per set | 20-50Ton, conventional equipment around 35T |

| 27 | Footprint (of a building, piece of equipment etc) | Conventional equipment: a single set covers an area of about 400 square meters, multiple sets of joint groups save more space |

| 28 | Staffing | Conventional equipment: 3-4 people to operate, multiple sets of joint group more labor-saving |

| 29 | Oil handling | Filtration, blending, stirring, purification distillation, etc. |

| 30 | Production Cycle | Conventional equipment: about 20 days |

| 31 | Haulage | Conventional equipment: single set of 1~2 17.5m flatbed trucks, more sets are more economical |

| 32 | Installation period | Conventional equipment: a single set of about 20 days, two sets of about 30 days, more sets of joint group more time-saving |

Message

Related Products